On the Lean Organization

In a Nutshell:

Lean is a term used in business to describe a simplified and minimalist approach to doing business. The first principle of lean, at its base level, is to build only what is needed. In the lean environment, marketing is a key source of information for the manufacturing process. Understanding market demand is fundamental in responding properly because the most efficiently designed and built product is just waste if the consumer is unwilling to buy it. Therefore, reliable customer feedback is essential for keeping a product line focused on models and features that will sell. According to the Environmental Protection Agency (EPA), the lean methodology took off in the U.S. in 1980s as a way for companies to reduce overhead costs, streamline processes and production and eliminate waste. According to the Lean Enterprise Institute, lean concepts were exemplified by Toyota in the 1930s when Kiichiro Toyoda introduced the Toyota Production System. In the late 1980s, Jim Womack, MIT graduate and founder of the Lean Enterprise Institute, led a research team that coined the phrase “lean production” to describe Toyota’s concept.

Overview:

Lean organizations are firms that have adopted the lean methodology into their business model. Any type of company can implement lean concepts into its organizational structure as these concepts are not limited to production and manufacturing industries. For example, Seattle Children’s Hospital reports that through the use of checklists, continuous brainstorming and standardization, the medical facility is able to provide more efficient services to patients and make small improvements to eliminate waste.

The lean concept looks for ways to eliminate unnecessary resources so that companies can operate with less. The process begins by identifying things of value. Steps that do not contribute to the value stream should be eliminated so that processes can be completed in a tighter sequence. This should be a continuous process so that businesses are always examining things of value and determining how to achieve optimum performance.

According to the EPA, lean organizations are benefiting the environment. By operating within the lean methodology, companies are saving electricity and paper, reducing waste and getting rid of unnecessary chemical pollutants, all of which is good for the environment.

The Evolution of Lean Management

The origins of lean management, which is widely found throughout the business world, sprang from a simple concept. The core philosophy behind lean is that customers do not pay for mistakes or waste but value. As such, companies need to increase the value of their products or services in order to maximize profit. Lean management offers an opportunity to drive up value and promote continuous improvement.

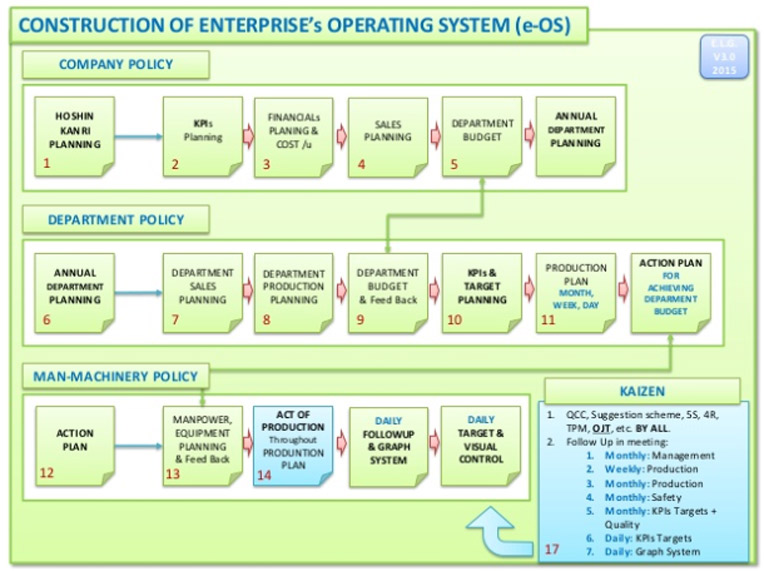

Implementing lean management enables a company to establish a sense of direction and create corporate objectives. Implementing lean systems enables a company to eliminate processes that do not offer value and track improvement via a set of reliable metrics. This form of management allows company executives to have a clear picture of what is working correctly for the company and what areas are in need of changes. Thousands of manufacturers remain profitable even during recession by using lean principles to become more cost-efficient. Lean management has proven to be an effective component to maintain a company’s sense of economic viability, even during rough financial times.

Lean Management in Operations

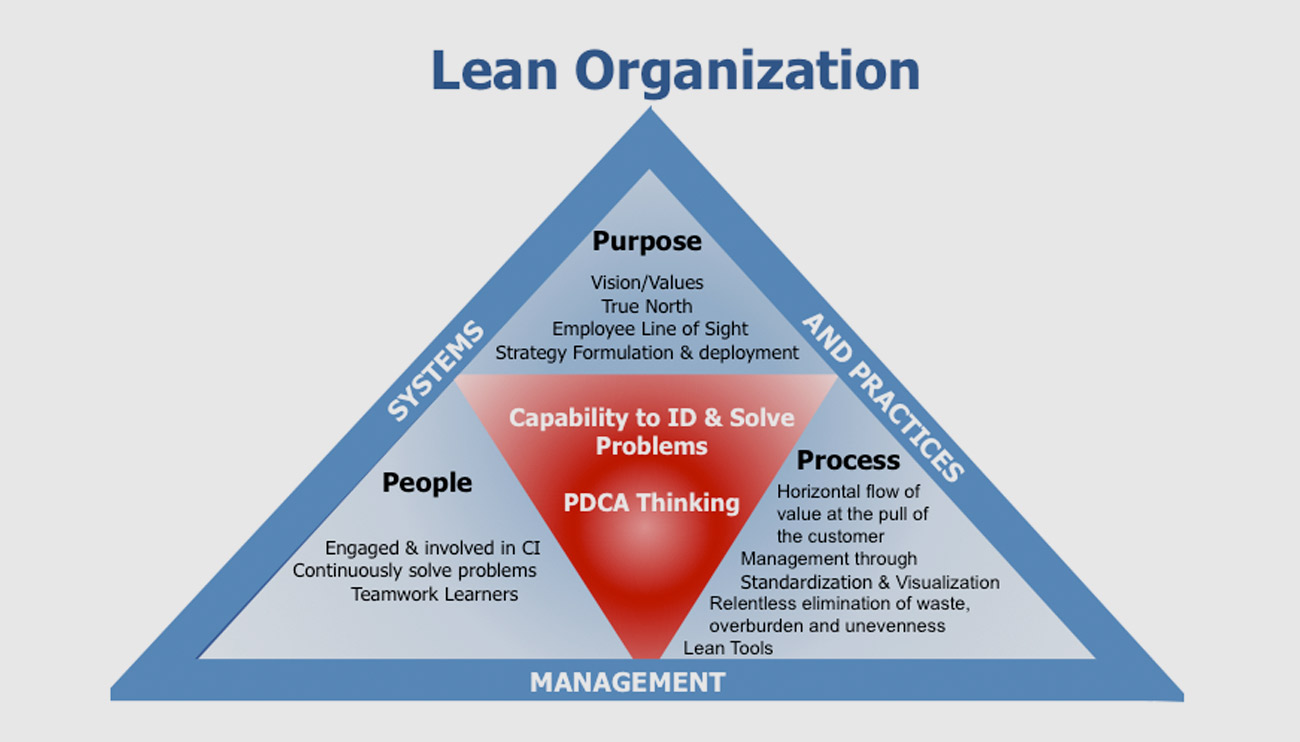

Lean management eliminates waste by examining processes and striving for continual improvement. Five inherent principles are involved in the implementation of lean techniques: identifying value, value-stream mapping, creating flow, establishing pull and seeking perfection. Personnel from a variety of departments are often brought together to examine a single process. This allows for a wide range of perspective and helps prevent a “this is the way it’s always been done” mindset.

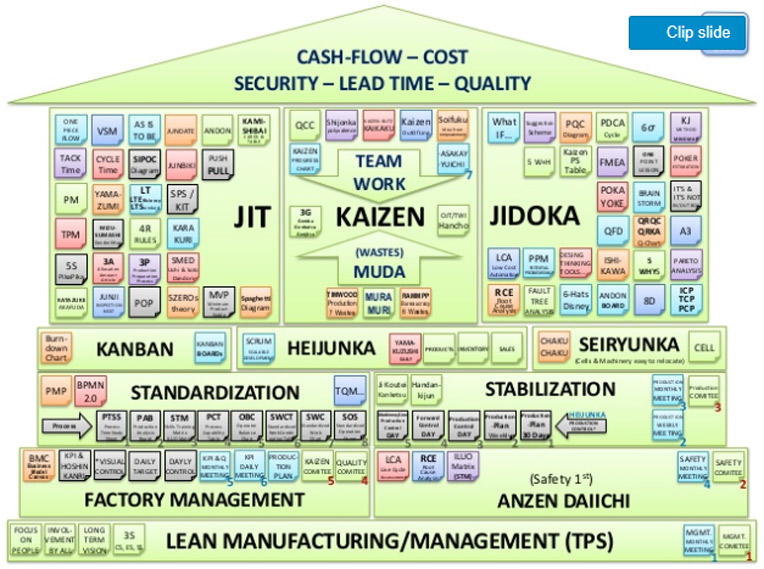

The prevailing theme of lean management is waste elimination which first requires identification of areas where wasteful actions occur. There are many potential wastes, including overproduction, inventory, extra processing steps, motion, defects, waiting and transportation. Employees involved in lean management need to examine processes and look for examples of these. Lean thinking has moved beyond the world of manufacturing and is now used by managers in a variety of disciplines. Lean management can now be found in such areas as construction, health care, government and maintenance. The companies in these industries which implement lean philosophy find greater awareness with regard to waste. Efficiency becomes a top priority and helps to maximize profit or reduce costs, as shown in the House of Lean Management below.

Lean Management Enterprise Metrics

An important part of lean management is developing a set of metrics with which employees can document their achievement. Metrics are used in business to identify trends and record progress towards the ultimate goal of eliminating waste. They are also necessary in promoting a lean system to all employees and providing a sense of purpose and pride for departments. Companies can use metrics as a basis for issuing bonus payments, and this encourages employees to be mindful of waste.

The two main pillars of lean management are:

- Respect for people: It is about giving people authority to solve their own problems. It is the responsibility of the lean manager to help employees identify their own problems and devise a problem solving technique for them and respect those decisions. As employees are given authority to solve their issues, their level of motivation to work according to the requirements increases which in turns increase the value of the end product for the customers. Respect is a two way road. Lean managers should give respect to the employees and also to the end customers.

- Continuous Improvement: In lean management, incremental changes are made for solving problems. Each problem is taken as a challenge and each solution is devised through a learning process which helps in leading towards continuous improvement. The small constant improvements are then turned into big improvements with time and thus the process goes on and on for achieving the final goal i.e. value creation for the customers.

As outlined in our Lean Management Systems Handbook ¹, it is very useful because ²:

- It helps in reduction of waste.

- It helps in elimination of defects in the products and processes.

- It helps to detect the faults in raw material and processes earlier so that the problem can be fixed before production starts.

- It helps in improving quality because of defect reduction.

- It helps in reducing the inventory.

- It increases production flexibility.

- It helps in boosting up employees’ morale by giving them respect and authority to a certain extend to solve their own problems and issues. ³

The Lean Management Systems Handbook

The book captures the essence of Lean learning and Lean doing and illustrates practical applications of Lean management. It begins by covering the basics that encompass Lean management and leadership in two critical areas: maintenance/control and improvement.

After reading this book, you will better understand how to see waste, measure waste, eliminate waste, and develop an active change improvement workplace. You will also gain the practical understanding required to determine which Lean tool is best suited to your particular need for supporting an organization-wide management system. Expounding on essential Lean concepts, this is an ideal guide to help new managers and leaders make the transition from theory to successful application in the field.

Complete with brief summaries and examples of the most important tools in Lean management systems development in each chapter, the book provides a reliable roadmap for deploying a Lean management system across your organization, and subsequently across your entire value stream.

PURCHASE BOOK¹ The Lean Management Systems Handbook, by Charon, Harrington, Voehl and Wiggin, July 11, 2014 by Productivity Press, Reference - 549 Pages - 79 B/W Illustrations, ISBN 9781466564350 - CAT# K16035. Performance management, the primary focus of a Lean organization, occurs through continuous improvement programs that focus on education, belief systems development, and effective change management. Presenting a first-of-its-kind approach, The Lean Management Systems Handbook details the critical components required for sustainable Lean management.

² Expounding on essential Lean concepts, this is an ideal guide to help new managers and leaders make the transition from theory to successful application in the field. Complete with brief summaries and examples of the most important tools in Lean management systems development in each chapter, the book provides a reliable roadmap for deploying a Lean management system across your organization, and subsequently across your entire value stream.

³ Positioning Lean as a management operational philosophy far beyond the traditional set of improvement tools, the book explains how managers at all levels of the organization can integrate Lean into their daily management activities. It defines the Lean philosophy as well as the beliefs and behaviors required to develop a thriving Lean company culture.